Active Magnetic Bearings

for Optimized System Efficiency and Enhanced Reliability and Sustainability

Advantages

We offer Powerflux™ Magnetic Bearings in radial and side by side combination configuration and Xcelflux™ Magnetic Bearings with a unique coil architecture. The unique advantages of Calnetix’s active magnetic bearings include the following:

Non-contact Support

Calnetix’s active magnetic bearings present unique advantages over conventional roller or fluid-film bearings when designing high-speed rotating machinery. Unlike conventional bearings, AMBs suspend the target rotor in a magnetic field. The result is a non-contact rotor support system with extremely low friction and no contact wear. Some of the benefits of contactless magnetic bearings include:

- Low power losses and heat generation

- Higher achievable speed

- Low audible noise

Low Vibration Transmissibility

Calnetix utilizes an adaptive synchronous force rejection algorithm to minimize vibration transferred from the rotor to the housing. Low transmitted vibration is important in high-precision applications related to food, medical and defense industries. The benefits of low vibration transmissibility include:

- Minimizes magnetic bearing structural vibration

- Reduces magnetic bearing dynamic loading

- Reduces MBC power consumption

- Significantly lowers audible noise

Health Monitoring and Diagnostics

Calnetix’s active magnetic bearing product set up is easy, and it allows the user to monitor the health of the magnetic bearing system. Calnetix’s AMBs include a position sensor, a magnetic actuator and a microcontroller, making machine health monitoring and diagnostics readily accessible. With a connection to an external computer, identifying, analyzing and archiving the health and historical performance of the machine are all possible with advanced diagnostics. Health monitoring can be enhanced with the addition of Calnetix’s high frequency data capture hardware and interface.

Some of the health-monitoring features include:

- Easy monitoring with live vibration

- Ability to monitor bearing loading in all axes

- Ability to record advanced data and fault logging

- Optional data acquisition add-on to provide higher-quality and higher-resolution data

State-of-the-art Approach to Integrated Machine Design

In most cases, Calnetix utilizes broad multidisciplinary in-house expertise to work with a customer to design an entire machine on magnetic bearings, rather than simply supplying magnetic bearing components. This achieves optimal performance of the machine as an integrated system and fully realizes the magnetic bearing system potential. Some of Calnetix’s competitive advantages include:

- A wide range of in-house areas of expertise, including mechanical, electromagnetic, rotordynamic, thermal and electronic design and analysis

- Refined proprietary design and optimization codes that allow for quicker generation of optimized magnetic bearing geometries with fewer iterations

- Analytical solutions derived from the combination of in-house and third-party FEA modules

Advanced Graphical User Interface

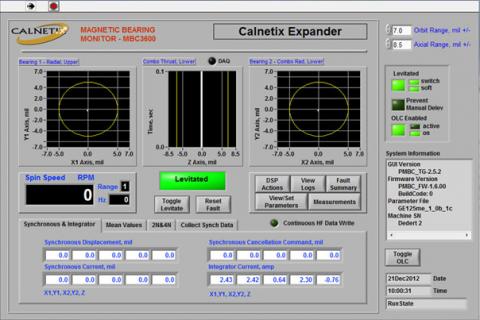

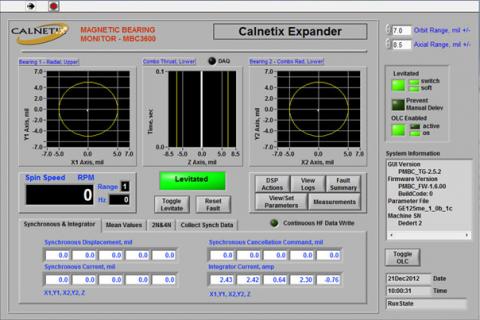

Calnetix developed a novel Graphical User Interface (GUI) to give both users and specialists an intuitive way to work with the inherent benefits of a magnetic bearing system. This GUI has been continuously refined and upgraded based on feedback from both internal and external customers. The GUI provides insight into all aspects of magnetic bearing and machine performance. It is the platform for system setup, monitoring and diagnostics:

- Automated mechanical clearance checks

- Automated electrical connection tests

- Levitation of the rotor to any desired position for operation or testing needs

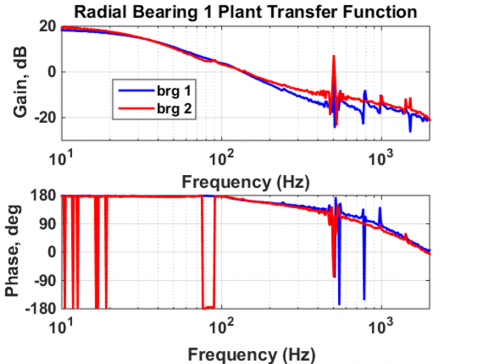

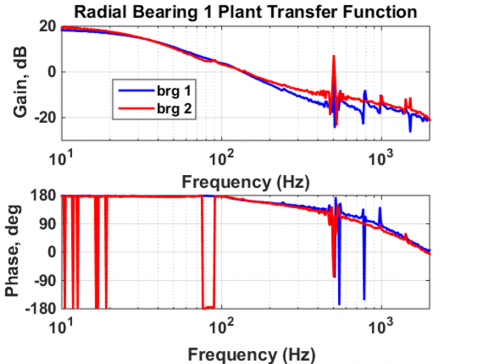

- Commissioning made simpler with built-in transfer function and frequency response tools

Products

Powerflux™ AMBs utilize homopolar permanent-magnet-bias magnetic fields in conjunction with an electromagnetic field, whereas Xcellflux™ AMBs use heteropolar electromagnetic bias fields in conjunction with electromagnetic control fields. Both products are low-cost and easy to assemble, as shown and described below.

PowerFlux™

XcelFlux™

PowerFlux™

- Permanent magnet (PM) bias

- Homopolar design

- Combination of radial and axial bearing

- High performance with low power losses and low cooling requirements

- Suitable for high performance and precision applications, including defense, space, power generation and less than 1 MW oil and gas compressors and expanders

COMPONENTS

Magnetic bearings do not function on their own; they require multiple components working together as a unique system. Calnetix has designed and developed all of the components that make up the active magnetic bearing system, and these components are shown and described below.

Actuators

Position Sensors

Speed Sensors

Backup Bearings

Magnetic Bearing Controller

Graphical User Interface

Actuators

The actuator in an active magnetic bearing is the electromagnet that applies a controlled force to the shaft of a machine to control its position. A radial actuator consists of a lamination stack with control coils and poles arranged to give two orthogonal axes of control. An arrangement of permanent magnets is also used in Calnetix actuators to produce a linearizing bias flux. Other AMB manufacturers produce the linearizing flux with a DC current in the control coil. Two other common actuator configurations are a combination radial/axial actuator and a stand-alone axial actuator.

An AMB actuator must be connected to a Magnetic Bearing Controller (MBC) that supplies the control current to the coils based on a position sensor feedback signal and a control algorithm.

To learn about the operational principle of homopolar, permanent magnet-biased active magnetic bearing, please click here.

Position Sensors

Position sensors are critical components of any active magnetic bearing. Their role is to continuously provide the controller with accurate up-to-date information about the rotor position unaffected by the external factors, such as speed, temperature, dust, working fluids, external magnetic and electrical fields, etc. Even though significant progress has been made in developing self-sensing AMBs, wherein the functions of the position measurement and the force generation are combined in one physical component, their fundamental performance limitations will likely limit their use to low-cost, low-speed machines. A conventional bearing arrangement utilizing dedicated radial and axial sensors will remain dominant.

Different types of position sensors have different combinations of properties, making some of them more suitable for a given application than the others. However, in the industrial environment, it is typically preferable to have one technology that would cover as many applications as possible. From a wide variety of the available technologies, including optical, capacitive and electromagnetic position sensors, the latter appears to be the most universal solution. Calnetix utilizes four types of sensors, depending on the application specifics:

- Radial Reluctance Sensors

- Axial Reluctance Sensors

- Constant -Flux Axial Edge Sensors

- CBR Eddy-Current Sensors

All sensors include the sensitive element (sensor head) located in the machine, where the displacement needs to be measured, and sensor electronics, typically located in the Magnetic Bearing Controller (MBC).

Speed Sensors

A speed sensor provides the active magnetic bearing with information about the rotational speed and the angular position of the rotor needed for adjusting the control parameters as speed changes and enabling the rotor unbalance cancellation. Calnetix uses two types of dedicated speed sensors. Both sensors utilize a source of a DC magnetic field, a Hall-effect element measuring that field and a feature on the rotor, such as a notch modulating the magnetic field.

- Smart Speed Sensors - The smart speed sensors utilize a built-in magnet as a source of the magnetic field, two Hall-effect sensors for the differential field measurement and an internal logic that looks for a periodical pattern in magnetic field variations over time, which is then interpreted as speed. Since these sensors are designed to look for any periodic pattern of the magnetic field, regardless of the levels, they do not need any calibration and are very easy to use. On the downside, they do not offer any flexibility in sensitivity adjustments, which may be needed in some applications.

- Programmable Speed Sensors - These sensors utilize two programmable Hall-effect sensors and an external source of the magnetic field. The parameters of the programmable Hall-effect sensors can be adjusted to address specifics of a particular application. These sensors are often integrated into the “dead poles” of the radial actuators to take advantage of the already available actuator bias magnetic field. This significantly reduces axial length of the machine and allows for greater rotordynamic margins.

Backup Bearings

Backup bearings provide support for the rotating assembly when the magnetic bearing system is deactivated, and provide rotor support in the event of an overload of the magnetic bearings or a failure of some component of the magnetic bearings. In normal operation, the backup bearings are not active as they will have a small radial and axial clearance to the rotating assembly. This clearance is at most one-half of the magnetic bearing air gap and typically considerably smaller.

The most common backup bearing configuration used by Calnetix is two duplex pairs of angular contact ball bearings preloaded face-to-face (DF). This mounting requires the bearing outer races to be clamped – either hard or through a spring – on the outer race. Hybrid bearings with conventional SAE 52100 steel races and SiN3 balls are standard. Backup bearings for high-speed applications are usually cageless and use either a grease film, dry film lubricant or a light grease fill.

Magnetic Bearing Controller

Calnetix Technologies has developed and deployed advanced Magnetic Bearing Controllers (MBCs) that contain all of the elements necessary to operate magnetic bearing systems. The company currently produces two different MBC platforms in the Insight™ series and one in Concurrence™ series.

For more information, see the Magnetic Bearing Controllers product page.

Graphical User Interface

The Calnetix Service Graphical User Interface (GUI) is used for system setup, monitoring, diagnostics and system identification. The upper half of the front panel, shown below, displays orbit plots from the two radial bearing sensors and a time history plot from the axial bearing sensor. Other operating variables shown include spin speed, static current, and synchronous displacement and current. Status variables, such as levitation and fault status, are indicated as well. A system Information window on the right gives version information for the GUI, firmware, parameter file and machine serial number specifier.

More detailed information or functionality can be accessed through the action buttons: Digital Signal Processors (DSP) Actions, View Logs, Fault Summary, View/Set Parameters and Measurements. The additional functionality includes:

- Transfer function measurement- plant transfer function, compensator transfer function, open loop transfer function, closed loop transfer function and sensitivity transfer function

- Logs- fault, event, ESD data, machine specific calibration and system data

- Scope- internal high frequency measurements for key operating signals, such as rotor motion and coil current (actuator forces)

- Continuous data acquisition- long-term recording of high-frequency data, such as position, current and speed for disk storage

Why Use Active Magnetic Bearings?

Active Magnetic Bearings (AMBs) have been in commercial rotating machinery for over 30 years, offering increased performance and extended machine lifespan due to frictionless operation and the lack of wearable parts. There has been an industry-wide increase in the production of magnetic bearing systems, which has led to overall cost reduction and more rapid market adoption. Some of the advantages of switching to magnetic bearings, include:

- No physical contact between rotating and stationary components

- No lubrication system required (environmentally-friendly)

- Fully functional in harsh environments

- Low power losses

- Dynamic testing, health-monitoring and data-logging

- And many more…

To see more information about AMB advantages, click here.

Resources

View More

White Paper

How Magnetic Bearings Work

White Paper

How A Magnetic Bearing Controller Works

Advantages

Advantages of Magnetic Bearings

Technical Paper

Transient Simulation of Magnetic Bearing and Backup Bearing Interaction in a High Speed Rotary Atomizer Subjected to Impulsive Loads

Technical Paper

Design and Shop Testing of a 165kW Cryogenic Expander/Generator on Magnetic Bearings

Technical Paper

Comparative Study of Axial/Radial Magnetic Bearing Arrangements for Turbocompressor Applications