The Artificial Lift Solution

The Artificial Lift Solution To Increase Hydrocarbon Production and Recovery from Conventional and Unconventional Wells

Subsidiary Specifications

Upwing Energy, an affiliate company of Calnetix Technologies, provides the most reliable, available and retrievable artificial lift technology that increases the production and recovery of hydrocarbons from conventional and unconventional wells. Upwing Energy has developed a high-speed magnetically driven downhole compressor system with the goal of boosting the production rate and recovery in liquid-rich shale gas wells.

Solution

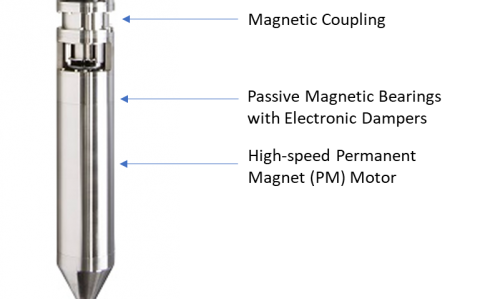

Upwing’s Subsurface Compressor System™ (SCS) was developed using Calnetix’s proprietary technologies, including a high-speed permanent magnet motor, magnetic coupling, passive non-contact magnetic bearings with electronic dampers and sensorless high frequency controls, which are able to control the frequency of the motor downhole without sensors via a long step-out.

Upwing’s SCS was deployed in an unconventional shale gas well with a 2,000-foot vertical wellbore and a 5,000-foot horizontal wellbore, where liquid had accumulated. The compressor was installed at the bottom of the vertical section with a tail pipe extending approximately 1,000 feet into the horizontal to provide enough velocity to carry liquids while minimizing friction losses. The installation was very similar to electric submersible pump (ESP) systems in that the SCS unit was tubing deployed, and the electrical cable with the instrumentation was secured around the tubing. This was the first time certain topside and subsea technologies were deployed successfully in the downhole environment.

The full-scale commercial SCS was deployed in an unconventional well field trial to:

- Reduce downhole flowing pressure to create higher reservoir drawdown that increases gas inflows and recoverable reserves

- Carry liquids to the surface by creating higher gas velocities throughout the vertical and horizontal wellbores

- Prevent vapor condensation by increasing the temperature of the gas when exiting the compressor

Challenges

The main challenge for Upwing engineers was to increase gas production and recoverable reserves from a liquid loaded, unconventional shale well with a horizontal wellbore.

Results

The trial resulted in a 62% increase in gas production and a 50% increase in liquid production over its steady-state performance with a rod pump prior to the SCS installation. Some other impressive test results include:

- The gas velocity increased to 29 feet per second and a high rate of liquid was carried to the surface when the SCS operated at 30,000 RPM.

- The hybrid axial compressor was able to atomize the liquid into a very fine mist, which together with the increased velocity and heat generated from the exit of the compressor helped carry the liquids to the surface.

- The compressor blades showed no sign of degradation despite moving a significant amount of liquids.

Click here to view a more detailed case study on Upwing Energy’s Website.

“Upwing Subsurface Compressor System” is a trademark of Upwing Energy, Inc.