Overview

The Pressure-to-Power Solution For Natural Gas and Hydrogen Applications

Subsidiary Specifications

Sapphire Technologies, a subsidiary of Calnetix Technologies, develops, manufactures and sells sustainable and reliable energy recovery systems for both natural gas and hydrogen industrial and commercial applications. These systems are designed to convert the energy wasted in pressure reduction processes into clean electric power without interrupting manufacturing or processing activities. The clean electricity produced can be used locally or sold back to the grid.

Solution

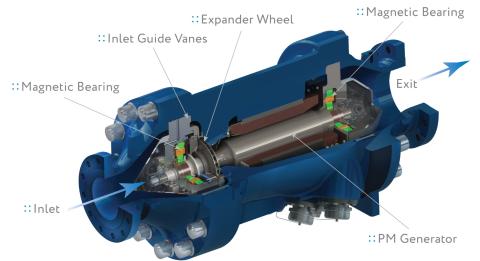

Utilizing Calnetix’s existing technologies and design support, a FreeSpin™ In-line Turboexpander (FIT) system was developed for the purpose of recovering waste pressure energy from natural gas and hydrogen industrial processes while reducing carbon impact on the environment. The basic underlying technologies in the FIT have been deployed by parent company Calnetix Technologies in multiple applications around the world.

The hermetically sealed in-line FreeSpin™ unit contains an integrated high-speed turboexpander that drives a synchronous permanent-magnet high-speed generator levitated on non-contact active magnetic bearings (AMBs). An AMB allows the dynamic components of the FIT to operate in a levitated condition, consuming very little energy and eliminating maintenance as compared to conventional bearings. The flow-through architecture directs the gas flow across the stator and rotor of the generator and provides cooling to both. The power electronics for the FIT combines the Variable Speed Drive (VSD) and Magnetic Bearing Controller (MBC) into one cabinet. The VSD allows for a consistent and clean delivery of generated power from the FIT to the grid.

Challenges

The first challenge was that the turboexpander must be installed in a hazardous area, since natural gas or a flammable gas is being used as process fluid. The second challenge was that higher pressures and lower temperatures were required for this application, compared to previous flow-through machine designs.

Results

In order to address the flammable gas hazardous zone, Sapphire engineers made the following designs adjustments to the FreeSpin™ system:

- The turboexpander housing is hermetically sealed.

- Explosion proof connectors are used for electrical connections.

- Electronics are designed to be placed outside of the hazardous zone.

A new cast housing design was also made for this machine with a low temperature alloy.

“FreeSpin” is a trademark of Sapphire Technologies, Inc.

Contact Us Today

See what Calnetix’s high-speed solutions can do for your business.