How PM Motor Generators Work

High-speed permanent magnet machines possess many desirable attributes that make them attractive for direct drive applications in various industries. This has been made possible with the advent of high-performance permanent magnets with high energy density and high operating temperature, providing the permanent magnet (PM) motor with industry leading power density and efficiency. The sensorless control is also very popular for high performance PM motor control. Calnetix’s PM motors’ robust rotor construction provides operations at higher speeds with larger turbo wheels, and their associated power electronics are less costly and simpler to use.

PM motors consist of two basic parts. A stator coil, powered by an alternating current, creates an electric field. Then a rotor made of high energy magnetic material rotates within that field. Today’s high-speed PM motors employ the latest technology in high strength rare earth magnetic materials to achieve high power density and efficiency. The former leads directly to minimum physical size at all power levels when compared with other motor types; the latter leads to significant improvements in overall system efficiency.

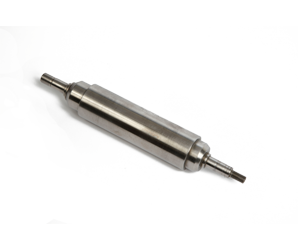

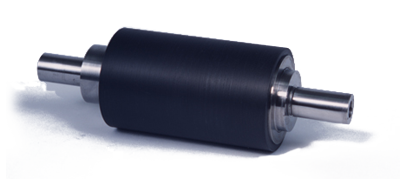

Calnetix currently uses two primary types of rotor construction to provide high speed rotating assemblies in mass production.

Containment is provided by either a high strength metal sleeve or a proprietary advanced graphite-composite sleeve for tip speeds in excess of 1200 feet per second. Both offer unique advantages to the system and motor/generator performance. Calnetix selects the optimum approach to meet system performance goals and is experienced in utilizing both approaches in development and production.

Other rotor design criteria include operating temperatures, type of bearings employed, stiffness required, operating bending modes and operating gas or liquid medium.

Calnetix addresses all these factors when designing PM machines, and thoroughly understands the required characteristics of the rotor for each application or working environment.

Calnetix applies PM motor technology over an expansive speed range to address a broad spectrum of application requirements. Designs that operate over 450,000 rpm have been achieved, with 30,000 to 100,000 rpm being the typical operating range for Calnetix machines. Available in air-cooled or liquid-cooled configurations, these PM machines offer:

- Robust rotor construction, maximizing rotor stiffness for higher bending mode frequencies

- Fewer rotor poles, reducing stator losses by lowering drive frequency requirements

- The latest technology in stator lamination materials to minimize stator iron losses

Calnetix system designs based on PM motors and generators have the following attributes:

High Efficiency

Efficiency measures how effectively energy is utilized in a system. Maximizing this energy usage to perform the desired work minimizes wasted energy. The PM motor/generator technology offered by Calnetix offers the highest efficiencies available for high speed machines. These high efficiencies are optimized for your specific application, taking into account the desired output, size restrictions, cooling, etc.

High Speed

High-speed machines allow for a directly driven high-speed system, eliminating the low-speed motor-gearbox arrangement to provide a high-speed drive shaft output. A high-speed PM motor generator can directly drive, or be driven by, a high-speed turbine, compressor or other turbomachinery. High-speed machines offer significant reduction in motor generator size, as well as reduced motor generator cost and simplified integration. Integration of these small, highly efficient machines into the coupled equipment further reduces cost and complexity.

High Temperature Capabilities

Calnetix Technologies uses the latest in permanent magnet (PM) and insulation materials, and is continuously working with leading magnet and insulation manufacturers to increase the temperature capabilities and other performance characteristics in its PM machines. Depending on the rare earth magnets utilized in the machines, temperatures up to 550°F can be achieved. Calnetix utilizes class H and above insulation systems for its high performance stator windings to push the rated temperatures well above 180°C. Most standard motors are limited to temperatures below 160°C.

Calnetix has developed in-house analysis tools to consistently explore and help optimize operating conditions during integration of the motor generator into any high-performance system. One great example of a high-temperature application that Calnetix currently produces is a PM machine for gas turbine systems. The turbine impeller, operating at approximately 900°C, is directly connected to Calnetix’s high-speed generator rotor shaft. Calnetix has mastered the analysis of these types of critical systems and produces PM machines that operate efficiently and reliably.