Overview

Hybrid Turbocharger System for Ships Using Permanent Magnet Motor Generator Technology and a Bidirectional Variable Speed Drive

Customer Specifications

Mitsubishi Heavy Industries, Ltd. (MHI), the leading marine equipment manufacturer was looking for next generation of energy recovery systems that can enable the company to generate a significant amount of power from the engine’s exhaust energy onboard marine vessels while remaining compliant with international rules and regulations concerning the marine environment.

Solution

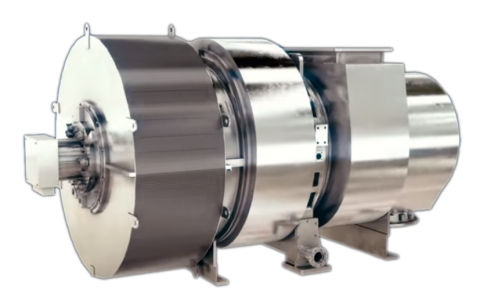

Calnetix designed and built a high-speed permanent magnet (PM) motor generator that fits inside the silencer of MHI’s existing hybrid turbocharger, resulting in a very small footprint that is a mere 313 millimeters longer than its conventional counterpart. By diverting a small portion of the engine exhaust gas that would normally be dedicated entirely to the marine turbocharger, the hybrid turbocharger has the capability to provide all the auxiliary power necessary for the average ship and potential for saving thousands of dollars in fuel cost per day. When the ship is at cruising speed, the integrated Magnaforce™ generator, driven by the marine turbocharger rotor shaft, produces electrical power equivalent to up to five percent of the main engine output. During slow steaming, by acting as a motor, the permanent magnet machine’s turbo assist capabilities enhance the performance of the main engine.

For hybrid turbocharger installation, the motor generator was optimally designed to match the turbocharger shaft speed and also to be fully compatible with Calnetix high-frequency power electronic drives.

Challenges

While developing the hybrid turbocharger, the permanent magnet generator was downsized so that it could be installed in the silencer. The main problem encountered during the design was the cooling structure of the PM generator. The passage of cooling water and air, and lubricating oil for the generator from outside were integrated in the generator’s housing during the downsizing. The time-proven sliding bearing of the turbocharger was adopted for the generator bearing without modification. The generator seal structure with the sealing air and labyrinth seal prevented lubricating oil from leaking into the input shaft and the stator. Also, the electricity generated from the hybrid turbocharger that supplied the entire electrical demand of the ship during normal cruising was processed by an inverter to maintain the correct output power frequency and voltage as well as to ensure the power factor of the ship and to maintain capacity to supply the required short-circuit current.

Results

After the installation, it was observed the turbocharger not only recovers electric power from excessive energy in the engine exhaust gas, but also controls the air sent to the engine for combustion by controlling the power-generation rate. Both fuel consumption and CO₂ production were reduced. The hybrid turbocharger used exhaust-gas energy at the turbocharger inlet port to generate electricity, just as a conventional gas power turbine does. However, compared with a conventional power turbine, our hybrid turbocharger provided the following advantages:

- Only a few modifications to the engine were required to install the turbocharger, and retrofitting was relatively easy, resulting in only a slight increase in the external dimensions because exhaust-gas piping and valve controls were not required.

- The system was free from thermal and piping losses, and the turbocharger turbine provided high efficiency.

- The turbocharger was accelerated by utilizing the high-speed generator as a motor.

Contact Us Today

See what Calnetix’s high-speed solutions can do for your business.