TURBO & SUPERCHARGING

Calnetix Technologies’ electric turbocharger and supercharger systems with Magnaforce™ motor generator technology and Vericycle™ power electronics technology help you get more power and performance from your engine at any operating condition with less fuel consumption and low carbon emissions. The key benefits of Calnetix’s electric turbo system are:

-

Optimal air/fuel ratio under any given engine condition for enhanced performance

-

Electric power production from engine exhaust

-

Engine downsizing technology for the same power output

-

Increased fuel economy

-

No turbo lag

-

Compact, power dense footprint minimizes space required for motor generator systems

-

Compact and high temperature power electronics simplifies integration with motor generator unit (MGU) in engine compartment

-

Low cost integration

-

Rapid payback

From one to 1,000 HP, Calnetix has numerous electric turbo systems in operation today in applications ranging from light vehicles and motorsports to marine transportation.

Turbocharger Applications

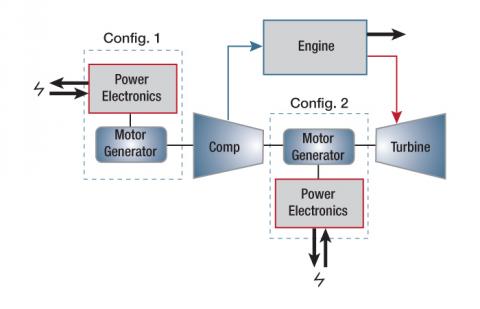

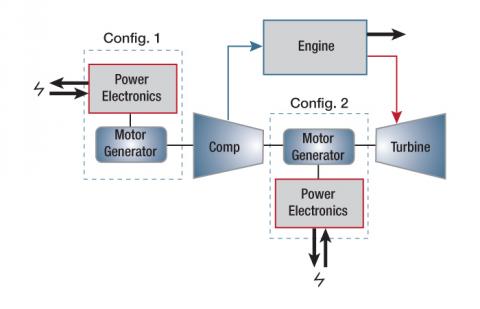

Calnetix Technologies’ e-turbo systems or electric turbocharger enable the turbocharger to perform independently of the engine exhaust conditions. This means the compressor performance is decoupled from the exhaust turbine performance, and can therefore provide the necessary air/fuel ratio for optimum engine performance under all load, speed, start/stop and ramp up conditions.

The motor generator unit (MGU) of an e-turbo system can be a standalone unit directly coupled to the turbocharger shaft or be integrated between the compressor and turbine for optimum compactness. At startup, the MGU accelerates the turbocharger from low idling speed to maximum speed, as high as 200,000 revolutions per minute (rpm), in a fraction of a second. This creates the necessary boost to eliminate turbo lag and enhance engine torque generation for optimum vehicle acceleration.

When the turbocharger is at steady-state operation, the same MGU can be operated in generator mode to produce electrical power from the excess engine exhaust pressure. This energy can be used to run ancillary systems or charge vehicle batteries, improving overall vehicle efficiency.

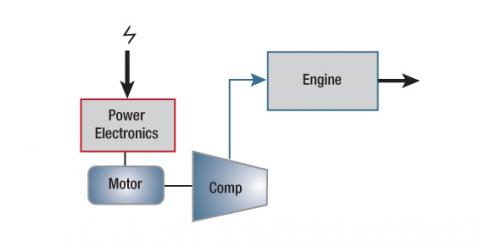

Supercharger Applications

An electric supercharger also known as e-charger or e-booster consists of a high-speed electric motor driving a compressor to provide compressed air to the engine’s combustion chamber, creating a steady boost especially during startup and low-speed engine operation. The high-speed motor can be directly coupled to the compressor, but is more often integrated on the same common shaft. Comparing to other motor technologies, Magnaforce™ motor technology with permanent magnet excitation has lower rotor inertia and stator winding inductance, resulting in superior transient response. The motor’s response is instantaneous and it can be turned on and off as needed. Calnetix has vast experience in optimizing Magnaforce™ motor design for supercharger applications to enhance system integration and overall operating efficiency.

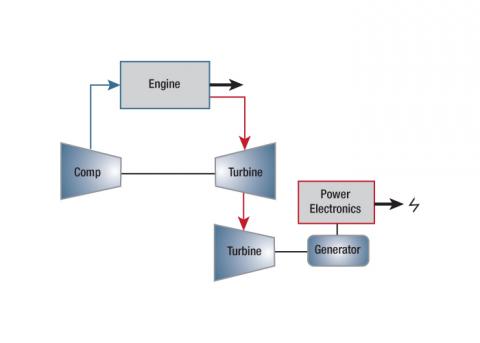

Compounder Applications

A turbocompounder is a standalone turbine and generator system that utilizes the waste energy exhaust either from the engine directly or in most cases downstream of the engine’s turbocharger to produce electric power. The additional electric power produced is approximately 7 to 8 percent of the engine capacity. Turbo-compounding helps improve overall engine fuel efficiency, while providing an attractive return on investment (ROI). Calnetix’s highly efficient, high-speed direct drive generator technology is well suited for turbo-compounding applications.